Behold The 650-Horsepower W12 Engine Of The First Bentley Bacalar

If you're one of the 12 wealthy individuals who have been waiting for their Bentley Bacalar, you'd be glad to hear that a part...

Behold The 650-Horsepower W12 Engine Of The First Bentley Bacalar

If you're one of the 12 wealthy individuals who have been waiting for their Bentley Bacalar, you'd be glad to hear that a part of one customer-bound unit of the £1.5-million (~$1.91-million) roofless grand tourer has already been completed – though we're sure you already know about this.

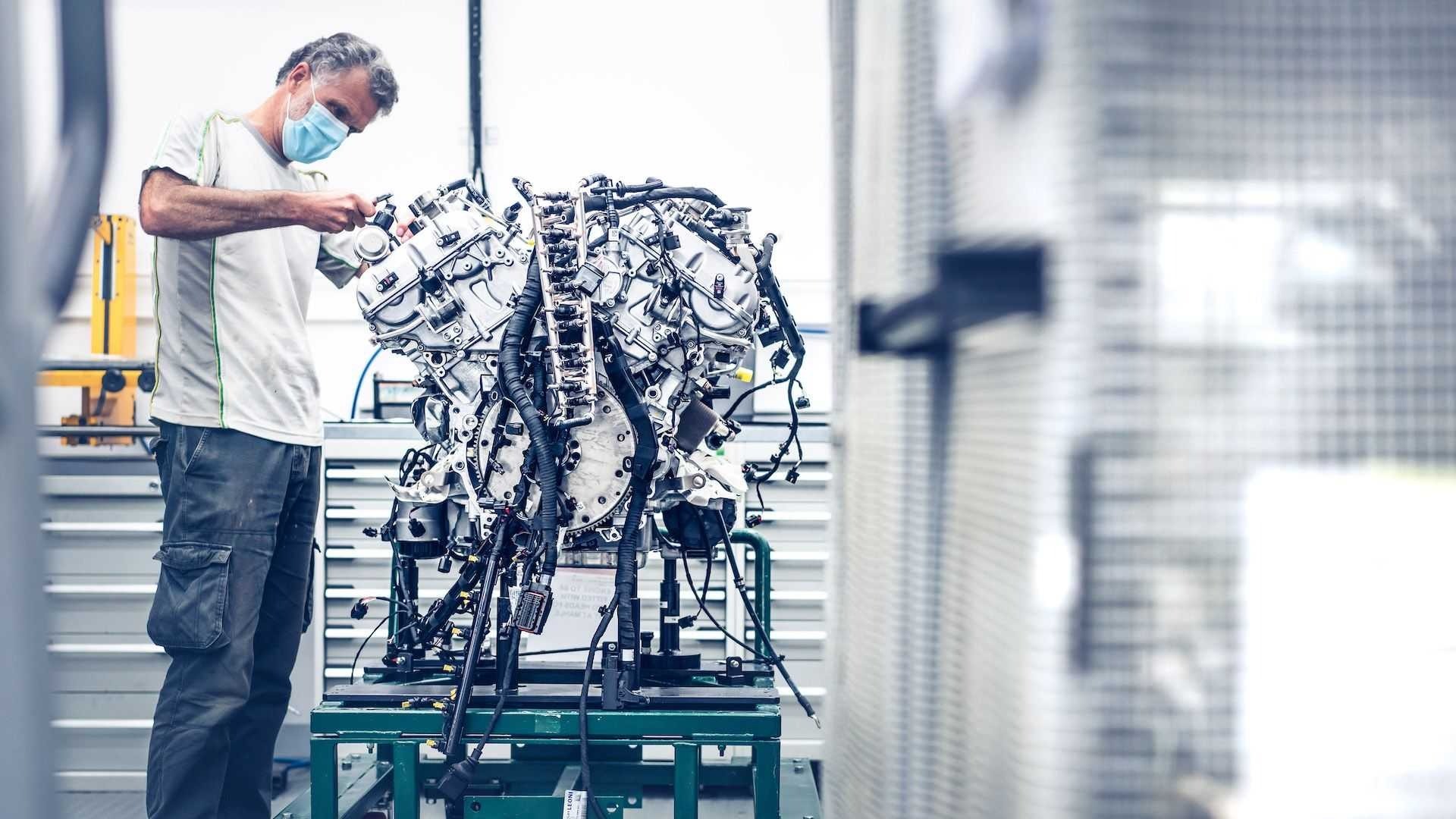

Bentley announced that the first W12 engine for the Bacalar has already been built in Crewe and more importantly, it already completed the British marque's three-stage testing. According to the automaker, the W12 is the most advanced 12-cylinder engine in history.

As you should know by now, the latest evolution of the twin-turbo 6.0-liter W12 engine churns out a massive 650 horsepower (485 kilowatts) and the same 667 pound-feet (900 Newton-meters) of torque. Compared to the first Bentley W12 in 2003, the latest version, which was introduced in the Bentayga SUV in 2016, has an increased power by up to 27 percent, torque by 38 percent, and reduced emissions by 28 percent.

Bentley subjects each W12 engine to rigorous testing that can be categorized into three categories. The first test is for leakage, checking if there's any fault in the closed fuel, water, and oil systems.

The second test is the most advanced and is called the Cold Test. At this stage, Bentley measures 600 individual properties and characteristics of the engine during a 15-minute cycle. It's done at a low running speed of 120 RPM, allowing fine details and any inconsistencies to be identified, if any.

The third and final test is called the Hot Test, which checks the complete engine assembly once parts are installed, then simulating real-world usage in the Bacalar.

Of note, over 100,000 W12 engines have already been hand-built in Crewe since 2002, with each motor going through the hands of 45 craftsmen over 6.5 hours of production.